Cereal Bar Production Line

Sold

Cereal Bar Production Line

Description

PROCESS

A slab extruder feeds the product on to the belt

Three drum rollers compress the product into desired thickness

Auto chillers provide the ambient cooling in the drum rollers and cooling tunnels to help firm up the bars

Inline circular knives slice the bars as it passes through

An encoder measures the distance of the belt travelled so once the product has travelled the set distance, the belt stops and a guillotine blade cross-cuts the bars

Bars off-load to another conveyor for packaging

Running at top speed, this production line should produce approx 250 bars per minute for a 5″L x 1″W bar.

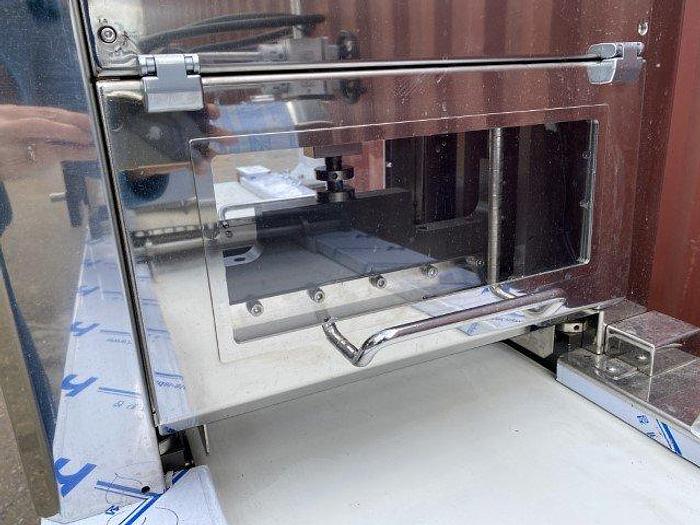

Cereal Bar Line

Conveyor belt: 310″L x 13.5″W

Three rum rollers: 19″ diameter x 11″W

Two cooling tunnels: 38″L, aperture: 11.25″W x 1.5″H

Inline circular knives set 1.125″W

Guillotine blade: 13″W

Dimensions: 310″L x 36″W x 66″H

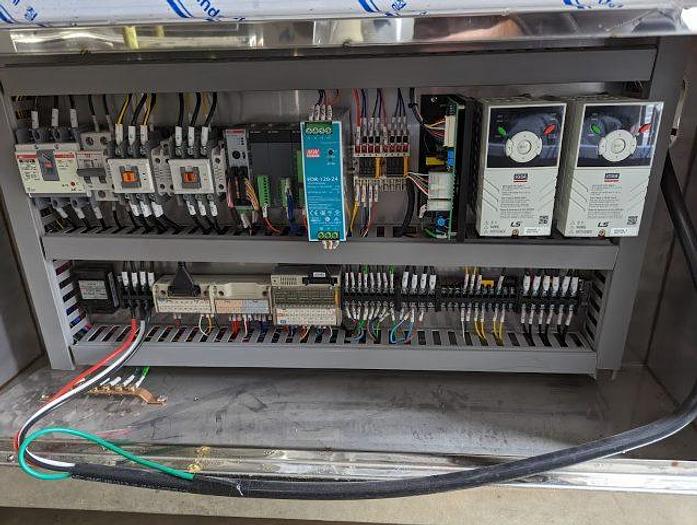

Slab Extruder

Hopper infeed: 17″ x 17″, 11″ deep to auger, infeed height: 61.5″ from ground.

Auger powered by a DKM induction motor.

Two drums, each powered by a Motovario gear motor.

Discharge chute: 9.5″L x 11.5″W

Dimensions: 42″L x 40″W x 64″H

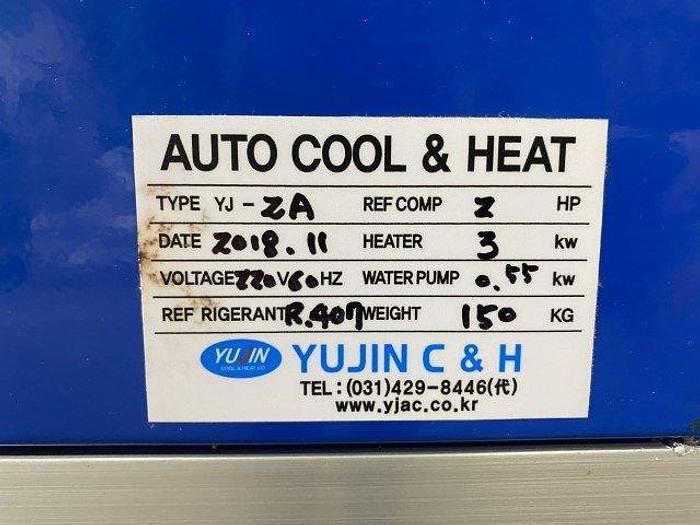

Auto Chillers 1 & 2

Type: YJ-2A

Power: 220 V | heater 3 kW, water pump 0.55 kW | 2 hp

Refrigerant: R407

Dimensions: 26″L x 40″W x 41″H (the one with hose is 46″H)

Auto Chiller 3

Type: YJ-5A

Fan cage: 24″ diameter, 5 fan blades approx 8″L x 4″W

Power: 220 V | heater 6 k, water pump 0.75 kW | 5 hp

Refrigerant: R407

Dimensions: 29.5″L x 55″W x 60″H

condition: Good

Specifications

| Condition | Used |

| Stock Number | 3470 |