USED PROCESSING AND

PACKAGING EQUIPMENT LEADERS

Menu

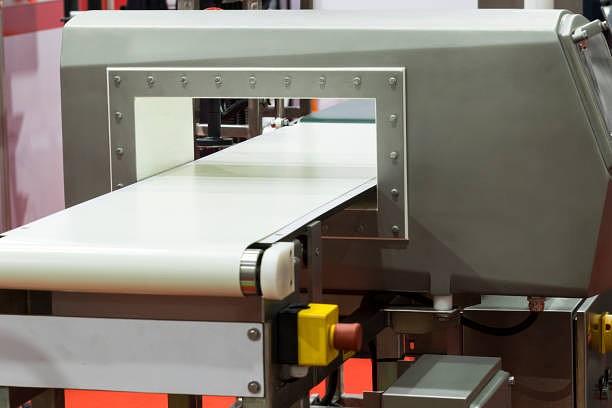

Comprehensive Guide: Metal Detectors in Food Processing

How Metal Detectors Work

Metal detectors create a magnetic field to find metal pieces like iron, aluminum, or stainless steel in food. How well they work depends on the type of food and the design of the detector. Some foods, like salty ones, can make it harder to detect metal, so the machines need to be carefully adjusted to catch any unwanted bits.

Types of Metal Detectors

- Conveyor-based: For packaged goods

- Gravity-fed: For powders and granules

- Pipeline: For liquids and viscous products

- Vertical/free-fall: Before packaging

Reject systems include air blasts, pushers, and diverters to remove contaminated items.

Choosing Equipment

When choosing equipment it's important to consider aperture size, sensitivity, reject method, and ease of integration. For used units, inspect condition and support availability.

You should also consider the difference between metal detectors and x-ray systems:

- X-ray systems detect a wider range of contaminants but come at a higher cost. The choice depends on product type and risk assessment.

Looking to Buy?

At Steep Hill Equipment Solutions, we offer a wide selection of new and used metal detectors for food processing. Each unit is tested and ready for production, with expert support to help you choose the right system for your line.

Canada: (604) 425-2002

USA: (405) 310-7562